HD ceramic machine Punching Cutting Machine for 9H Anti Broken Ceramic Matte Screen Protector Film Cover Protector

Application

Punching & cutting machine mainly suitable for positioning hole processing in electronics, signage, packaging, printing and other industries such as: FPC coil material, film coil material, PET coil material, self-adhesive film material, film coil material, etc.

Characteristics

1.Automatic light-sensing unwinding: as long as the processing material is outside the infrared sensing range, the unwinding machine will automatically unwind and provide the material length required for the next feeding;

2. Automatic roller guide frame: the product passes and the surrounding guide block is fixed to ensure that the product always maintains the same direction;

3.Dust-removing and anti-static function: a dust-removing and anti-static roller is installed on the work surface, which can remove the dust and static electricity on the surface of the product;

4.Fast directional positioning: the directional positioning function is configured on the worktable to ensure that the product does not appear to be biased during the long-distance pulling process;

5.CCD image precise positioning: CCD industrial camera precise positioning to ensure accurate positioning of the product, there will never be a phenomenon of partial hole leakage;

6.Punching die: The punching die adopts imported high-speed steel and precision grinding and vacuum heat treatment to ensure the accuracy and service life of the die;

7.Man-machine interface display: The punching machine adopts man-machine interface display, which can watch the punching situation synchronously;

8.NC servo feed: NC servo feeder adopts imported Japanese servo feeder, PLC programming, can set 30 steps, each feeding accuracy to ensure 0.01mm;

9.Light-sensing chase color locator: light-sensing chase color can control the accuracy of punching;

10.Discharging speed: can be adjusted at will, the starting frequency is slowly increased from 0 to running, to avoid starting too fast, causing scratches on the surface of the material;

11.Punching speed: This equipment uses the HS series software independently developed by our company, high-speed stable motor, high-computing industrial computer, and the punching speed can reach 0.6 seconds/2 holes.

Technical Parameters

|

Model |

ND-350DQ |

|

Power |

0.4-0.5KW |

|

|

2100*1000*1100mm |

|

Weight |

400kg |

|

Package dimension |

3000*1600*1700mm |

|

Package weight |

450kg |

|

Punching diameter |

Φ1-Φ5.0mm |

|

Identification circle diameter |

Φ1-Φ5.0mm |

|

Punching thickness |

0.05-1mm (depending on the material) |

|

Punching speed |

0.6s/hole |

|

Processing accuracy |

≤±0.015mm |

|

Maximum processing width |

350mm |

|

Air pressure requirement |

0.6-0.8mpa |

|

Maximum impact force |

7000N |

|

Working voltage |

AC220-240V |

|

Use environment |

Air conditioning |

|

Light source |

Transmit infrared, reflect infrared |

|

Feeding method |

Servo feeding |

|

The maximum diameter of the coil is less than |

800mm |

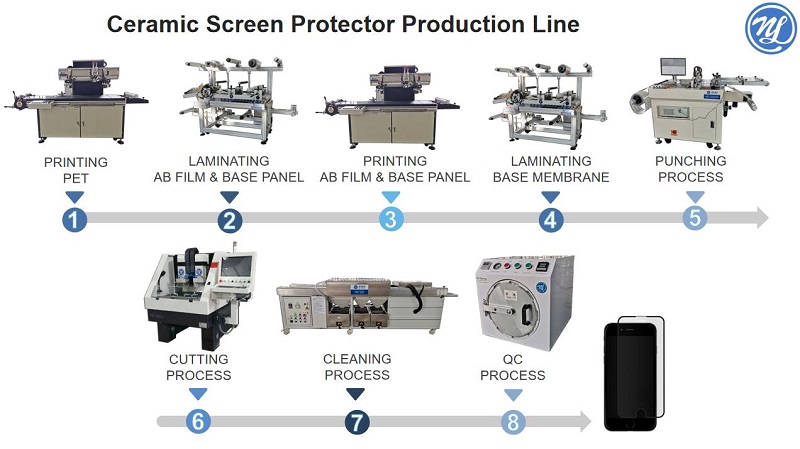

For moble screen ceramic film protector production line need a whole production line, the flow chart as follow:

沪ICP备16043421号©2013 恩迪 版权所有