Ceramic Screen Guard Machine Printing Machine for 9H Anti Broken Ceramic Matte Screen Protector Film Cover Protector

Application

Printing colors on the PET, Panel etc

Characteristics

1.Feeding-printing-oven full tension control.

2.The whole machine includes:

1).Automatic feeder (automatic feeding, static removal, tear film, no material stop function);

2).Automatic printing machine (dust removal cleaning, automatic alignment, printing and pulling position are servo motors, 220V power socket);

3).Hot air dryer (automatic feeding, 40m drying, ion fan, with cold air device, additional LED lamp, compound paper function, printing machine shutdown function, hopper blocking device);

4).Rewinding device (vertical).

Technical Parameters

|

Model |

ND-450SY |

|

Power |

22kw |

|

Weight |

2000kg |

|

Package dimension |

7500*1550*2200mm |

|

Package weight |

2200kg |

|

Automatic feeder |

|

|

Maximum unwinding diameter |

450mm |

|

Working voltage |

220V |

|

Maximum power |

0.4kw |

|

Automatic printing |

|

|

Maximum frame size |

700×800mm |

|

Maximum printing area |

380×480mm |

|

Material thickness |

0.1-0.5mm |

|

Feeding width |

50-400mm |

|

Registration accuracy |

±0.1mm |

|

Overprinting method |

Single-eye alignment |

|

Scraper stroke |

600mm |

|

Printing speed |

1500-2500 times/hr |

|

Printing servo motor |

0.75kw |

|

Feeding servo motor |

2kw |

|

Suction motor |

0.75kw |

|

Air working pressure |

5kg/cm2 |

|

Working voltage |

3-380V |

|

Hot air dryer |

|

|

Receiving maximum roll diameter |

450mm diameter |

|

Drying length |

40m |

|

Temperature range |

room temperature to 160 degrees |

|

Working voltage |

3-380V |

|

Maximum power |

18kw |

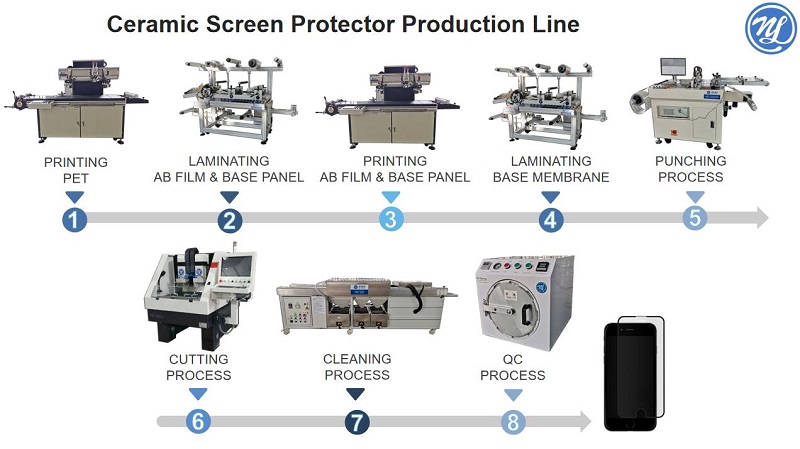

For moble screen ceramic film protector production line need a whole production line, the flow chart as follow:

沪ICP备16043421号©2013 恩迪 版权所有